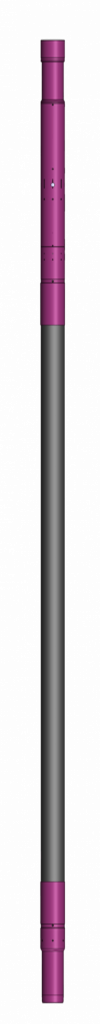

Hydraulic Packer for Collar Cementing PGMC is applied for collar cementing and to ensure separation

of filtering and cementing parts of liners and isolation of gas-, oil- and water-bearing formations.

The packer PGMC consists of two devices combined in one body: a hydraulic packer and a cementing

collar. The collar part of the device is the system of mechanically interconnected bushes fixed on

shear bolts that overlap cementing slots and the entrance to the under-hose cavity. The design of

the packing part is similar to the design of PGP packer.

The packer works as follows: before cementing, a ball is dropped into the transport string and pumped

until setting down a seat. With pressure build-up to 4,0 MPa ± 10% bolts are sheared off and the

plug is moved down until bumping the shoulder thus opening liquid access to the valve system of

the device packer part. After that the pressure is dropped down to 0 and the valve system prepares

the packer to actuation. On subsequent pressure build up to 6-8 MPa the hose inflates separating

hermetically cementing and noncementing parts of the liner in the outer annular space. The following

pressure relief to 0 switches the valve system and shuts liquid access to the packer part of the device.

PGMC2 and PGMC4 packers work in the similar way, but they do not require pressure release for

preparation of the valve system for packer setting.

The next cycle of the pressure build-up to 16 (14,5; 14) MPa opening of cementing ports is performed. After mixing and displacing of cement slurry, the hollow cementing plug (together with the

top cementing plug) is set down to the seat and after the internal overpressure build up to 5 MPa it

closes cementing ports and fixes its position.