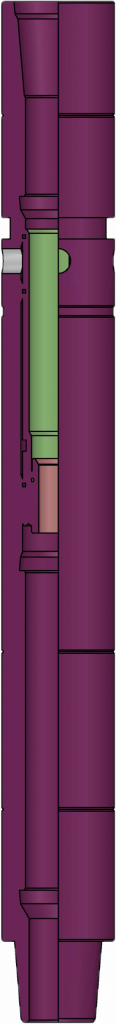

The Pressure Test Device is applied for drill string or tubing string pressure testing and

gaging. The device is included into the drill string during well bore preparation to casing

string running in. It is installed at the adjusted depth. After all the necessary elaborations

and flushing a plug is started at the bottomhole. After the drill string volume pumping up to

PO the plug is set into a seat. Drill string pressure testing is performed with gradual pressure

build-up. When the pressure 25,0±2,5 MPa is reached shear bolts are cut off and a bush is

moved against the bottom sub butt thus opening ports in the body.

The produced modification PO2 has a significantly lower hydraulic hammer effect with washout ports opening.

| PARAMETER DESCRIPTION | VALUE | |||

|---|---|---|---|---|

| PO-NKT 73 |

PO-NKT В-73 |

PO.000 | PO.102 | |

| Drill string nominal diameter RIH with the device, mm |

73 | 73 | 73; 89 | 73; 89 |

| Maximum outer diameter of the device, mm | 89 | 93,2 | 121 | 105 |

| Drift diameter of the device, mm | 30 | 30 | 40 | 30 |

| Maximum internal overpressure, MPa ±10% | 30,0 | |||

| Length of the device fully assembled, mm | 830 | 830 | 857 | 911 |

| Device weight, kg, not more | 28,3 | 31,4 | 59 | 51 |

| Maximum tensile FORCE1, kN (tn) | 2000 (200) | |||

| Washout ports opening pressure2 , MPa ±10% |

25 | |||

| Maximum operating temperature3 , °C |

100 | |||

| Connecting threads: (top and bottom) according to GOST R 50864-90 (TU 3668-00-7-1403-00-39-2005) |

73 GOST 633 |

В-73 GOST 633 |

Z-102 | Z-86 (З-83) |

1

Calculated value when stresses reach yield point of the material.

2

Actuation pressure with all the shear bolts.

3 Reference only, depends on operating conditions of general mechanical

rubber goods in a well.