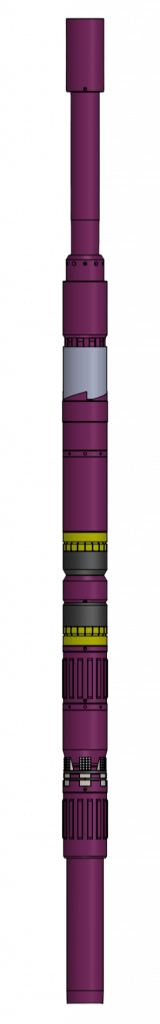

The PHNV liner hanger is used to RIH and hang non-cemented liners, providing the capability to rotate an assembly while running.

PHNV liner hangers, can be produced in UIF (unit of isolation of filters) configuration, allowing to perform circulation through the liner shoe.

PHNV liner hanger consists of four functionally independent components:

- anchor to hang the liner assembly in the casing string;

- hydro-mechanical packer to isolate annular space;

- hydraulic release mechanism that allows to RIH liner assembly, circulate, activate anchor/packer by hydraulic pressure and, then, disconnect the drill string from PHN1 by applying hydraulic pressure.

- mechanical disconnection to back up a hydraulic release mechanism.