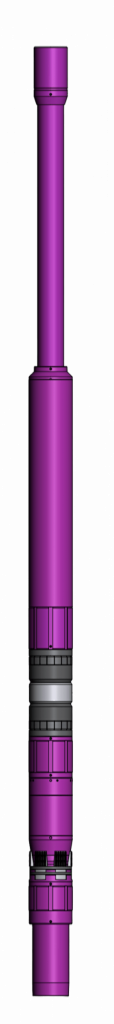

Liner Hanger with disconnection before cementing PHRC is designed for RIH, hanging and

liner sealing in the well.

The device is a complex of three stand-alone and independent units on the same body:

• anchor unit which ensures liner hanging in service string;

• mechanical packer unit which ensures sealing in of inner annular space;

• mechanical breaking unit which ensures RIH of units together with the liner, performance

of technological operations such as washover, actuation of anchor unit, mechanical

disconnection of the transport string from the device, liner cementing followed by

packer unit actuation.

The hanger consists of two parts: adjustment tool and the hanger itself, the latter includes

packer unit, anchor unit and lead-in funnel.

When using hangers like PHRC the following technological operations are performed:

• RHI of the device as a part of a transport string liner;

• washovers with limited pressure (no more than 75% of anchoring pressure);

• washover of the bottomhole without pressure limits (anchor actuation changes annular

space insignificantly);

• ball-drop and its driving until its setting in the PGMC packer seat or in a special seat

set above the check valve;

• PGMC actuation (for collar cementing);

• anchor unit actuation with internal overpressure build-up to 13 MPa;

• the pressure build-up to 16 MPa opens PGMC packer cementing ports (for collar

cementing) or the pressure build-up to 20 MPa leads to shearing of a special seat

with a ball to restore circulation;

• disconnection of an adjustment tool from the hanger through relief of the transport

string and its rotation to the right at least 10 times;

• performing of liner cementing with running of the cementing plug after the injection

of the cement slurry for its separation from the displacement fluid;

• displacing the cement slurry to the outer annular space of the liner and receiving of

“stop” signal;

• packer unit actuation by partial uploading of the transport string weight onto the “head”

part of the liner;

• washover and pulling out of the transport string.