РаLiner Hanger with two kinds of release before cementing is performed before cementing

РаLiner Hanger with two kinds of release before cementing is performed before cementing

operation in two modes: hydraulically and mechanically.

Liner hanger consists of following individual hubs: packer, anchor and setting tool.

Assembly has a row of locks from premature response:

• Packer is actuated after release and pulling out of setting tool by partial putting on weight

of the string;

• Mechanic release is provided by rotating the string clockwise.

This assembly allows provide the following operations:

• Run in the hole w/liner;

• Provide intermediate well circulation;

• Activation of assembly starts after drop and circulation of drop-ball down to the sitting

saddle ;

• Actuating the anchor by pressure up to 140 atm and putting weight on the liner;

• Provide release the liner from the drill string by pressure up to 180 atm or by turning the

string cloclwise;

• Disconnection is checked out by picking up the string to ensure pressure drop;

• Run in back in the hole and pressure test;

• Restore the circulation by raising the pressure up to 220 atm to shear the seat with the ball;

• Cementing through top plug to separate cement and squeezing fluids;

• Attaching of cement plug to hollow hanger-plug installed in the string assembly;

• Attaching of top cement plug to hollow hanger-plug installed in the string assembly;

• displacing the cement slurry to the outer annular space of the liner and receiving of “Bump”

signal;

• Circulate to wash excess cement solution from the top of liner;

• Actuation of liner packer assembly and hanger with partially putting weight and unloading

the string on thrust sleeve.

Liner Hangers

- Protected liner hanger for stage cementing PHZSC

- Noncemented retrievable liner hanger PHN-E

- Noncemented liner hanger PHN1

- Noncemented liner hanger PHN2

- Noncemented liner hanger with oriented whipstock PHN-KO

- Liner hanger with disconnection before cementing PHRC

- Rotating protected cemented liner hanger PHCZV

- Protected cemented liner hanger PHCZ

- Rotating non-cemented liner hanger PHNV

- Protected hydro-mechanical cemented liner hanger PHGMCZ

- Hydro-mechanical cemented liner hanger PHGMC

- Cemented liner hanger for flush-joint pipes PHCBT

- Liner hanger assembly, revolving while cementing PHVC

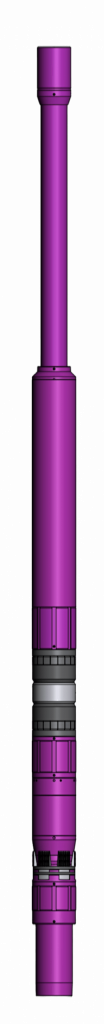

- Liner Hanger with two kinds of release before cementing PHGMRC

Liner Hanger with two kinds of release before cementing PHGMRC

| PARAMETER DESCRIPTION | VALUE | |

| PHGMRC 127/178-114 |

PHGMRC 178/245А |

|

| Conditional liner-pipe diameter equipped with the tool, mm | 114 | 178 |

| Conditional Casing diameter where the tool is run in and set, mm | 178 | 245 |

| Max outside diameter of the tool as per body (a/p centalizer), mm | 149 (152) | 211 (213) |

| Drift diameter after actuation, mm, not less than | 99 | 158 |

| Inner pressure when tension of tool parts reach the yield strength, MPA | 700 | 700 |

| Tensile load at which the body parts tensions are reaching the yield limit, kN |

700 | 1500 |

| The values of internal excess pressures for actuating tool units, MPa: – anchor unit – breaker unit |

13,0 |

|

| Max differential pressure between divided by hydraulic /mechanical packer areas, MPa |

70 | 300 |

| Max operating temperature, °С | 150 | 150 |

| Connecting threads: – top Gov’t Standard 28487 (R 50864) – bottom¹ |

З-102 ОТТМ-1142 |

ЗЗ-133- ОТТМ178 |

1

The bottom thread is made as per Customer’s tech request