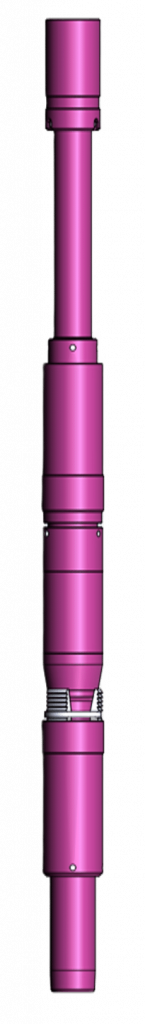

The PHN-E liner hanger is used to RIH and hang a small ID non-cemented liner, providingc the possibility to retrieve the liner if required.

This PHN-E liner hanger consists of 2 parts::

- anchor to hang the liner assembly in the casing string;

- hydraulic disconnection that allows to RIH liner assembly, circulate, activate anchor by hydraulic pressure and, then, disconnect the drill string from PHN-E by applying hydraulic pressure.

To retrieve the liner assembly, the spear (special tool) is run and set inside the PHN-E. The overpool of 5 ton is then applied to release an anchor and start pulling the liner out.