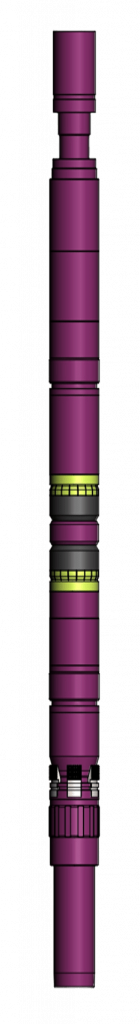

The PHCZ liner hanger is used to RIH and hang cemented liners and allows to sequentially perform well cementing operations, set hydraulic anchor, packer and, then, disconnect a drill string.

PHCZ liner hanger can be used in vertical, deviated, sub horizontal and horizontal wells, where it is required to run and cement a liner. PHCZ liner hanger consists of four functionally independent components:

- anchor to hang the liner assembly in the casing string;

- hydro-mechanical packer to isolate annular space;

- hydraulic release mechanism that allows to RIH liner assembly, circulate, activate anchor/ packer by hydraulic pressure and, then, disconnect the drill string from PHCZ by applying hydraulic pressure;

- mechanical release to back up a hydraulic disconnection.

After the liner is run to the bottom and required circulations (washovers) are carried out, PHCZ activation is carried out as follows:

- cement is pumped into a well and cement plug is lunched to separate it from displacement fluid;

- cement slurry is displaced into the liner-open hole annular space until the plug “bumps”;

- while well head pressure “on bump” increases, the hydraulic anchor gets set when pressure differential reaches 16 MPa. The pressure is passed through a hollow pin to the inner space of anchor’s fluid drive, which moves slips radially to latch on casing walls;

- hydraulic packer is activated simultaneously with anchor by differential pressure of 16 MPa. The pressure activates packer’s fluid drive, which creates force to a plunger sleeve to cut the shear pins and start moving while squeezing rubber seals split by centralizer: the seals deform and press against casing walls;

- when pressure differential reaches 20 MPa, the hydraulic disconnection device gets activated. The pressure on plunger creates force required to cut shear pins and move to release arresters, thus disconnecting the drill string from hanger;

- in case of problems with hydraulic release mechanism, the mechanical disconnection is activated by, first, adjusting weight indicator reading to the weight of the drill string in fluid and, second, rotating the drill string by 20 turns clockwise (to the right);

- circulation/washover is performed and drill pipe is POOH.

Depending on cementing job type required, the hanger/liner system is equipped with: for the “bottom up” liner cementing: The first liner pipe is equipped with a plug catcher, check valve and casing shoe. PHCZ is connected to the last liner pipe. for liner top cementing The first liner pipe is equipped with a shoe, the last liner pipe (in productive zone) is equipped with packer, such as PGMC, PGMC2 or PGMC4. PHCZ is connected to the last liner pipe.