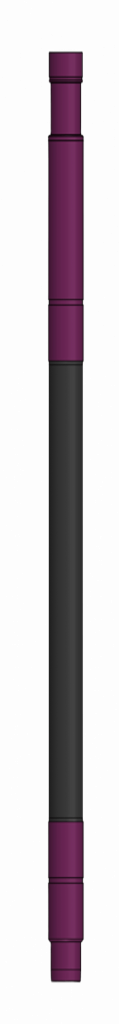

Collar Cementing Packer PMC is applied to ensure separation for cemented and noncemented casing string parts (liner) during collar cementing. The packer is used together with collar cementing

valve KMC.

The packer is produced in two designs, PMC and PMC-R that differ in the type of a sealing element:

• in PMC a sealing element consists of three sealing rings;

• in PMC-R a sealing element is a rubberized fabric hose.

The packer is actuated before cementing by a ball-drop and its pumping until setting down a seat

inside the packer. This leads to the deformation of a sealing element and packing of annular space

between the walls of a well and a casing string (liner).

The packer is equipped with a trip valve which ensures RIH without overflow.