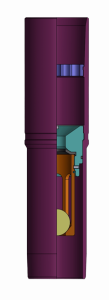

Ball Check Valve KOSH-type is applied for prevention of backflow of cement slurry or

drilling mud from outer annulus into inner space of a casing string with nominal diameter

89, 102, 114 and 127 mm.

Ball Check Valve KOSH2 is used in wells where casings (liners) with nominal diameter

89, 102, 114 and 127 mm are run in. Ball Check Valve KOSHBT is used in wells which

collarless casings with nominal diameter 102, 114, 120 and 140 mm are run in. Inner

parts of KOSH valves are made of aluminium alloy.

It is possible to mount KOSH2.114 and KOSH2.127 valves on pipes with thread OTTG 114

and OTTG 127, GOST 632-80.