Well screens design made by Research and Development Center “ZERS” LLC is based on survey of a great

amount of research works carried out by Russian and foreign researchers, as well as on results of longtime field experience of using such devices and recommendations of oil and gas production enterprises.

There are 2 types of well imperfection such as penetration degree imperfection and opening attitude

imperfection.

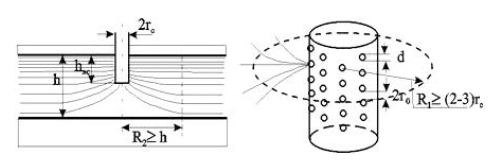

A well imperfect according to the penetration degree is a well with an open hole but it didn’t enter formation at full capacity, only partially (fig. 1a). A well though brought to formation bottom but connected with

formation only through holes in casing pipes, a cementing ring or a special well filter is called imperfect

according to formation penetration (fig. 1b). In practice these wells occur the most frequently.

Rate G of an imperfect well is most frequently lower that rate Gc of a perfect well, working in the same

conditions than this imperfect one.

a b

Fig. 1. Fluid inflow chart to an imperfect well:

a – penetration degree;

b – formation opening.

It should be noted that imperfectness of a vertical well influences less significantly on its productivity

that imperfectness of a horizontal well.

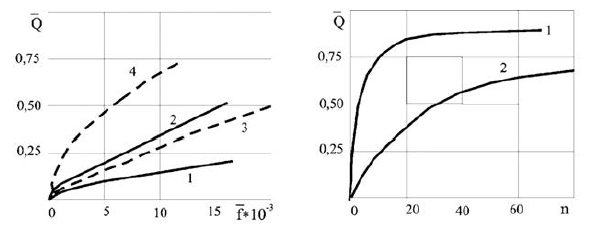

Research performed by V.I. Schurov through electrolytic modelling (fig. 2) revealed significant dependence of the rate from density of perforations only up to 16-20 holes for 1 m. Further increase of a number of holes in filter case doesn’t increase the rate but leads to causeless increase of economic costs.

It should be noted that well productivity penetrating anisotropic formation with less holes diameter and

a bigger holes number exceeds productivity gained from larger holes diameter but less holes number

(fig. 4.3, curve 2, 3, 4).

Fig. 4.3 Q dependence of f perforation porosity Fig. 4.4 Q dependence of the number of holes n

1 – anisotropic formation (d=6.3*10-3m); 1 – a=0.3, b=0.1;

2 – isotropic formation (d=6.3*10-3m); 2 – a=10, b=0.001

3 – isotropic formation (d=2*10-3m);

4 – isotropic formation (d=0.5*10-3m);

d – perforation holes diameter; f=fh/F; fh – holes surface

for 1 lin. m of perforated surface F

Without further reasons and calculations we should notice that LLC RDC “ZERS” considers the most efficient well filter design

including 28 holes with diameter 10 mm per 1 m.

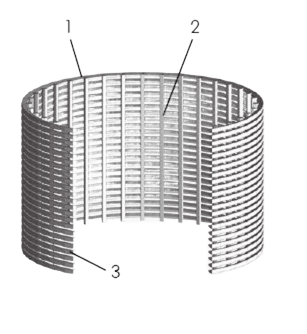

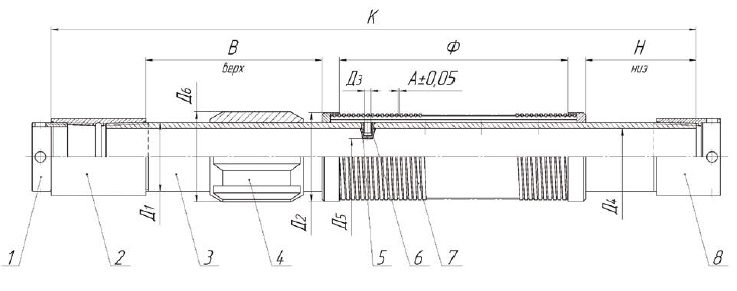

FS-type well filter is applied as a part of a casing string filtering part and is used to prevent destruction of productive

formation bottom-hole area and sand or other mechanical impurities intrusion. The filter is run into productive formation

and installed in a required interval of the well with the help of a liner hanger or as a part of a casing string. FS-type filter is

a device consisting of a case with holes on the outer side of which there is a slit-type filter element manufactured by spiral

winding of stainless steel wire with a special triangular section onto longitudinal load-bearing elements (stringers). The

length of the filter element, the gap size and a number of holes in the body as per 1 linear meter of its length are defined

by its intended operational conditions and are subject to approval with the customer.

FS filter is available in variants with hollow plugs “caps” (variant K) and without them. The plugs are installed in the holes of

the case and provide filter leak tightness up to 15 MPa of internal overpressure. It thus allows to washover a well through

a casing shoe. The hollow plugs are removed by mechanical destruction.

1 – Shaped wire.

2 – Stringer.

3 – Gap width (clearance).

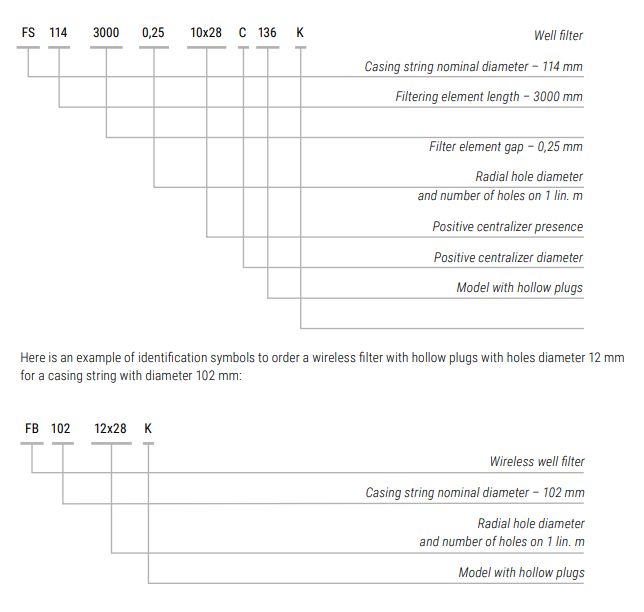

FB-type wireless filter differs from FS filter by lack of filter element on the case outer surface. It is also available

with hollow plugs “caps” and in plug-less variants. Maximum test pressure of a filter for the variant with hollow

plugs is 15 MPa.

Here is an example of identification symbols to order a well screen with hollow plugs for a casing string with diameter 114 mm with slit clearance size of 0,25 mm and filter element length of 3000 mm provided with a positive

centralizer with diameter of 136 mm:

1. Plug 2. Collar 3. Body 4. Solid centralizer 5. Hollow plug 6. Hub 7. Filtering element 8. Plug

1. Plug 2. Collar 3. Body 4. Solid centralizer 5. Hollow plug 6. Hub 7. Filtering element 8. Plug