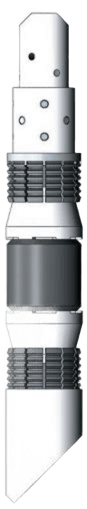

Drilled out Bridge Plug made of composite material is intended for leak-free isolation of

Drilled out Bridge Plug made of composite material is intended for leak-free isolation of

the required intervals zones in the well bore. The plug holds differential pressures up to

700 atm and can be used for multi-staged formation fracs (as per Plug&Perf technology).

After frac the plug is easily drilled out. The plug can be run in with any work-string using

special multi-usage setting tool. After getting to the planned set depth the setting tool

is activated by pumping down the ball to the seat spot in the setting device. Then, with

pressuring up setting and detachment of a plug from setting tool is made. The Plugs are

issued in several modifications: blind ones, with inner check valve, etc.

| PARAMETER DESCRIPTION | VALUE | |

| MPR.114 | MPR.146 | |

| Nominal casing diameter where run in and spot the bridge plug, mm |

114 | 146 |

| Max outside diameter, mm | 93 | 122 |

| Diameter of the flow channel through passage, mm | 23 | – |

| Plug activation pressure with installation tool, MPa | 16±5% | 16±5% |

| Max differential pressure on the plug, MPa | 70 | 70 |

| Length, mm, not more | 600 | 730 |

| Weight, kg, not more | 7,5 | 17,2 |